This transfer often occurs between human hands and electronics, which can result in harmful electric shock that can injure the individual, or interference, permanent damage and catastrophic failure of many different sensitive electronic devices, equipment and machinery. Read More…

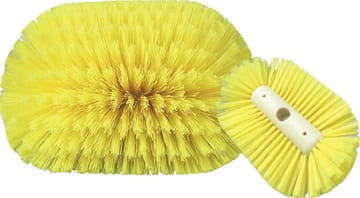

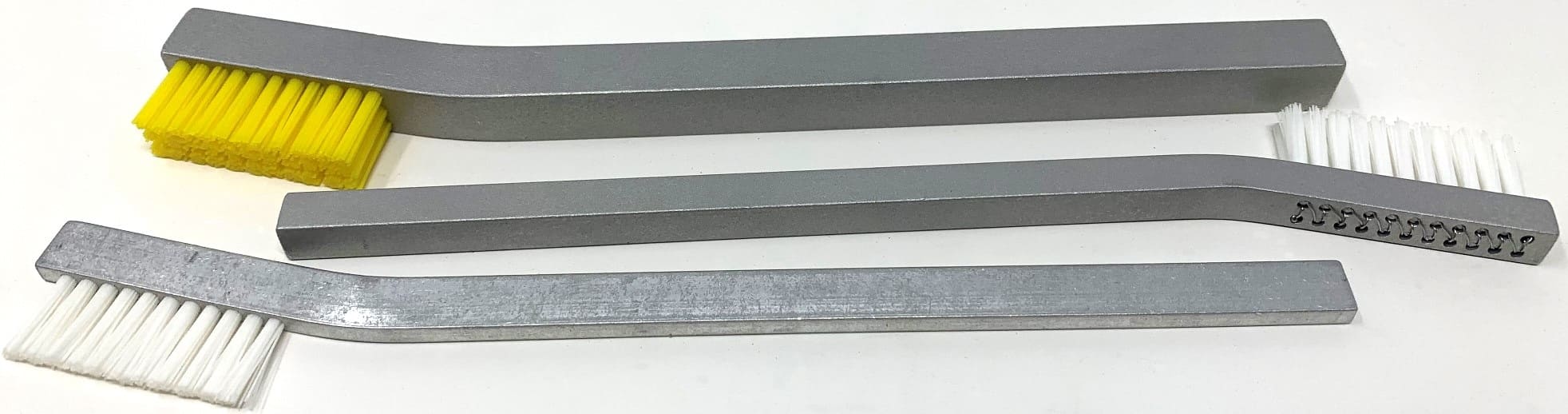

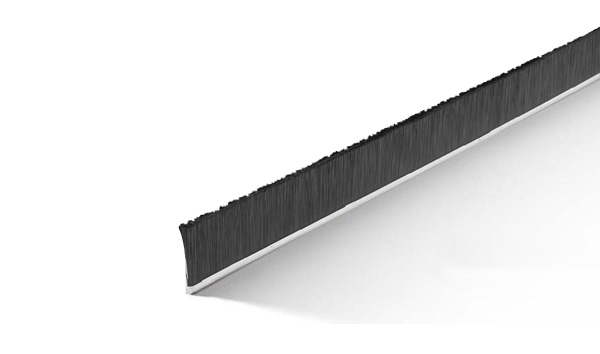

Gordon Brush’s® ESD & cleanroom products meet the specific needs of the electronics industry plus industries where static electricity buildup is detrimental to manufacturing.

TAKK Industries manufactures static eliminators for industrial processes and business machines. We also offer a full line of static eliminator blowers, spray, static detection meters and anti-static brushes. Some applications they can be used for are painting, plastic, textiles and more. If you have questions or need to meet certain specifications, don’t hesitate to contact TAKK Industries.

At Amstat Industries, we specialize in providing innovative solutions for static elimination, helping industries maintain optimal efficiency and safety in their operations. Our expertise lies in designing and manufacturing advanced static eliminators that effectively mitigate the challenges posed by electrostatic charges in a variety of industrial environments.

More ESD Product Manufacturers

While the electronic device may not undergo complete failure when subjected to ESD, it will degrade, which is product damage that results in a lower level of efficiency and reliability. However, there are several simple and effective products designed to guard against ESD, all of which are inexpensive and regularly used by computer repair technicians, clean room workers, lab technicians and workers assembling and manufacturing electronics, computers and cell phones. The products include anti static mats and gloves, ground straps, spray, bags and brushes.

These products ground, dissipate, conduct or balance any charge carried on an individual about to handle electronic hardware of any kind. Before anyone touches the internal components of any electronic device or equipment, it must be unplugged and the person must be grounded, which is the process of connecting with a conductor to transfer any ESD to another object, making sure there is no chance to transfer any to the hardware.

ESD protection comes in many different forms, which are all preventative. Static is generated very easily, and can be caused by two pieces of clothing lightly rubbing together. Once static has transferred from a hand to electronic hardware, the damage cannot be undone. The most popular, effective and inexpensive method is a grounding strap, often called a wrist strap. These are Velcro cuffs made of a conductive fiber material with a small piece of metal attached to a wire in the form of a braid, strip, mesh or wire.

That wire is connected to a grounding device like an anti static mat made of rubber and a grounding outlet. Anti static gloves are mostly used in electronics and computer manufacturing and assembly environments, where workers are continually handling sensitive, internal hardware. They prevent the static charge from transferring from a hand to the device by blocking the static.

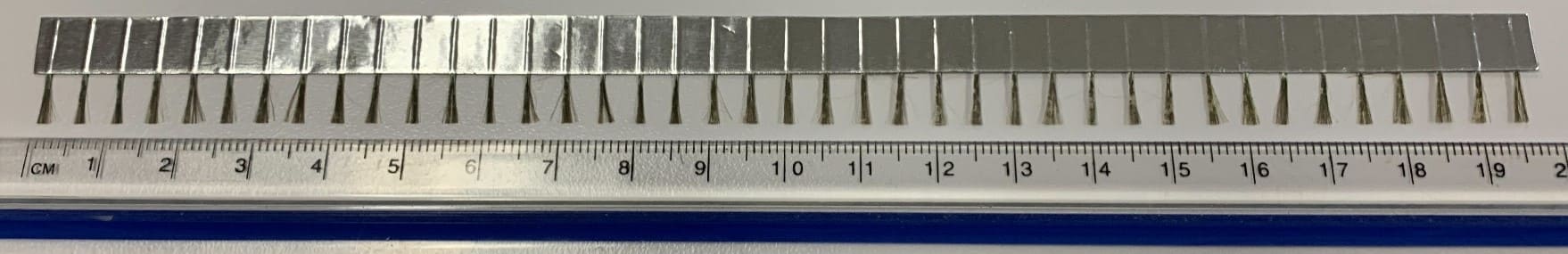

Static brushes are used when cleaning equipment, while anti-static spray prevents the occurrence of ESD by coating hard-to-reach places. Other less common options include ionizers, which neutralize static charges sitting on object surfaces, and corona treaters, which expose the object to electrical discharge as another preventative measure against ESD.

Electric Coils

Electric Coils Electric Switches

Electric Switches Electric Transformers

Electric Transformers Electronic Connectors

Electronic Connectors Electronic Enclosures

Electronic Enclosures EMI Shielding

EMI Shielding Membrane Switches

Membrane Switches Power Cords

Power Cords Static Eliminators

Static Eliminators Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services