Static eliminators are products that protect susceptible items from the effects of static discharge. These static shields are also known as antistatic (anti-static) devices, anti-static electricity devices, or static charge eliminators. They work by dampening, reducing, or otherwise inhibiting its buildup or discharge. Read More…

Gordon Brush’s® ESD & cleanroom products meet the specific needs of the electronics industry plus industries where static electricity buildup is detrimental to manufacturing.

TAKK Industries manufactures static eliminators for industrial processes and business machines. We also offer a full line of static eliminator blowers, spray, static detection meters and anti-static brushes. Some applications they can be used for are painting, plastic, textiles and more. If you have questions or need to meet certain specifications, don’t hesitate to contact TAKK Industries.

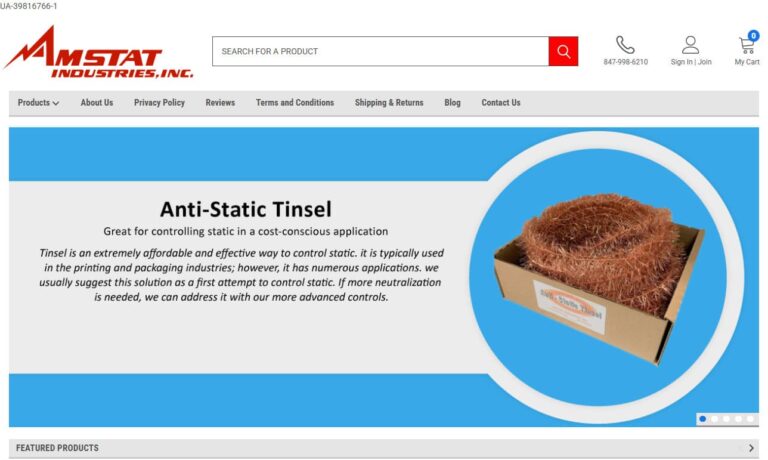

At Amstat Industries, we specialize in providing innovative solutions for static elimination, helping industries maintain optimal efficiency and safety in their operations. Our expertise lies in designing and manufacturing advanced static eliminators that effectively mitigate the challenges posed by electrostatic charges in a variety of industrial environments.

More Static Eliminator Manufacturers

Applications of Static Eliminators

Static discharge refers to the buildup of excess positive or negative ions in insulating materials, such as plastic, paper, glass, or film, when their molecular structure becomes unbalanced. This imbalance is often caused by separation, temperature changes, and friction between surfaces, which are common during industrial processing, packaging, and material handling. An excess of ions can lead to a wide range of issues—including equipment damage, minor electrical shocks, dust attraction, data corruption, and even fires or explosions in hazardous environments. Static eliminators (also known as anti-static devices or static control solutions) are engineered to mitigate these risks by neutralizing static charges before they can cause harm.

Static electricity affects various industries, including automotive manufacturing, electronics assembly, medical device production, plastics processing, printing and packaging, power generation, semiconductor fabrication, textile mills, pharmaceuticals, and even residential services such as floor care and electronics repair. Static eliminators effectively address static problems across these sectors, ensuring product quality, workplace safety, and operational efficiency.

- Electronics and Semiconductor Manufacturing: Prevents electrostatic discharge (ESD) that can destroy sensitive components or lead to latent defects.

- Printing and Packaging: Eliminates static cling that causes paper jams, misfeeds, and dust contamination; improves ink adhesion and print quality.

- Plastics Processing: Reduces dust attraction, improves molding outcomes, and prevents sheet sticking or web tears during extrusion and converting.

- Automotive Assembly: Ensures proper painting, finishing, and electronics installation by neutralizing static on parts and assemblies.

- Medical Device Production: Protects delicate circuit boards and sensors from ESD, and maintains sterile environments by reducing particle attraction.

- Textile Manufacturing: Minimizes lint, static shocks, and thread breakage on high-speed looms and sewing machines.

- Industrial Automation: Prevents malfunctions in robotic arms, conveyors, and sensors caused by stray static charges.

Are you dealing with static problems in your plant, lab, or facility? Explore top static eliminator manufacturers or contact a specialist for guidance on anti-static solutions tailored to your industry.

History of Static Eliminators

Humans have recognized static electricity since around the 7th century BC. Around 600 BC, Greek scientist Thales of Miletus documented that rubbing amber could attract dust and leaves. This effect, we now know, is due to friction generating static electricity. Later, Theophrastus, a student of Aristotle, described similar observations in his work “On Stones,” noting how certain materials like amber can attract other objects.

In 1600, British scientist William Gilbert distinguished between electricity and magnetism, a revelation that marked a significant departure from previous beliefs that the two were the same. Gilbert coined the term “electricus,” derived from the New Latin for “of amber,” referencing the ancient observations of amber’s electric properties. By 1646, the terms “electric” and “electricity” had become established in the English language.

Subsequently, global scientific interest in electricity surged. Benjamin Franklin famously demonstrated the connection between electricity and lightning by capturing an electric charge with a kite and key during a storm, leading to his invention of the lightning rod. In 1879, Thomas Edison further advanced the field by inventing the electric lightbulb.

In the early 1900s, the rise of electricity introduced the issue of static interference. By 1918, Canadian-American engineer Roy A. Weagant created the first static eliminator to address this problem, crucial for transatlantic wireless communications and military operations during World War I.

By 1948, engineers developed the transistor, followed by the integrated circuit in 1958. The digital age heightened the need for static eliminators. Extensive testing in the 1950s established ESD tolerance standards for devices. Today, with electricity usage soaring, engineers continuously innovate smaller, more sensitive anti-static technologies to counter static electricity. Modern static eliminators are integral to electronics manufacturing, cleanrooms, industrial automation, and even consumer electronics, reflecting decades of technological advancement and evolving safety standards.

How Static Eliminators Work

To effectively combat static electricity, two primary categories of static control solutions are used: active static eliminators and passive static control systems.

Active static control systems require an external power source to operate. These solutions are highly effective because they not only reduce static electricity but actively neutralize it. The most prevalent active solution is ionization, a process that neutralizes unbalanced charges and nullifies particle attraction, thereby preventing the generation and accumulation of additional static electricity. Ionizers emit a balanced stream of positive and negative ions, which attach to charged surfaces, equalizing their electrical potential. This approach is critical in environments where even minimal static can cause significant defects or hazards, such as cleanrooms, electronics assembly lines, and packaging operations.

Passive static control systems, on the other hand, reduce surface static charges by absorbing or redirecting them without the need for external power. Common passive solutions include grounding and electrostatic induction. Grounding works by establishing a direct electrical connection to the earth, allowing excess electrical charges to be safely discharged and dissipated. Electrostatic induction involves placing a material or object capable of developing an opposite electrical charge near the unbalanced item. When in close proximity, the static eliminator generates a corresponding set of opposite ions, thereby balancing the unbalanced charge. Passive solutions are often used for continuous protection in workstations, conveyor systems, and material handling applications.

Wondering which static control solution is right for your operation? Compare static eliminator types or contact a static control expert for advice on choosing between active and passive systems based on your industry requirements.

Types of Static Eliminators

Active Static Control Systems

Ionizers achieve ionization through a variety of methods, including chemical reactions, electrical discharge, radiation, high temperatures, and particle collisions. These static-eliminating devices can be divided into two categories: those that use alternating current (AC) and those that use direct current (DC).

One major benefit of AC ionizers is their natural ability to produce both positive and negative ions alternately, giving them an edge over DC ionizers, which require additional circuitry or power supplies to generate opposite polarity. AC ionizers are often preferred in environments requiring broad coverage and fast static decay, while DC ionizers offer precise control and are suitable for targeted applications in electronics manufacturing, medical device assembly, and laboratory settings.

Anti-static bars, also known as ionization bars, are effective in combating static cling and static buildup on fast-moving production lines. Typically, these bars are mounted above or alongside industrial product lines, such as those for plastic films, web materials, or sheets. By emitting an ionized corona through the air, they neutralize static electricity, ensuring the smooth operation of production processes and reducing downtime caused by material jams or dust accumulation. Some advanced models feature feedback sensors for real-time monitoring and adjustment of ion output, providing precision static control for high-value applications.

Ionizing blowers and nozzles are portable or integrated devices that direct streams of ionized air onto specific workspaces, parts, or equipment. These are ideal for spot-neutralizing static on assembly benches, packaging lines, or during maintenance of sensitive electronic components.

Passive Static Control Systems

Passive static control systems are essential in industrial and electronic settings, preventing static electricity buildup and discharge, which can damage sensitive equipment or pose safety hazards. Grounding straps and wrist straps are common grounding static eliminators, grounding machinery, and workers to prevent electrostatic discharge (ESD). These are standard in electronics assembly, repair, and quality control environments.

Static dissipative hoses, made from conductive or semi-conductive materials, ensure safe material transport by preventing static buildup during pneumatic conveying, dust collection, and material mixing. These hoses are particularly important in chemical plants, food processing, and pharmaceutical operations, where combustible dust or volatile materials are present.

Anti-static brushes and bags use induction to eliminate static electricity during cleaning tasks and protect electronic components from ESD during storage and transit. Anti-static mats and flooring solutions create static-free workspaces by discharging electric fields and maintaining surface conductivity regardless of environmental conditions. These solutions are commonly used in factories, cleanrooms, laboratories, and other sensitive work areas to ensure safety and operational efficiency.

Anti-static sprays offer a unique method of static elimination by coating surfaces with a static-deterring layer. Effective on high-charge surfaces and in hard-to-reach areas, these sprays are made from diluted soap-based materials and often include flame retardants. Anti-static sprays are ideal for treating carpets, packaging films, conveyor belts, and equipment enclosures. Anti-static gloves protect both equipment and workers from static electricity, offering ESD protection in electronics manufacturing, assembly, and inspection processes.

Corona treatment, while less common, serves as an effective surface treatment for static control. By exposing surfaces to an electrical discharge, it enhances bonding with adhesives and inks while preventing static buildup. This treatment is particularly useful in high-speed printing, label manufacturing, and any application requiring improved surface bonding and static protection. Together, these passive static control systems address the diverse challenges posed by static electricity in industrial and electronic environments.

- Looking for ESD-safe packaging or anti-static mats? Browse static control product suppliers

- Need to eliminate static in cleanrooms or manufacturing lines? Compare ionization and grounding solutions

How to Use Static Eliminators

Before initiating a static elimination procedure or installing static eliminators, it is essential for manufacturers, facility managers, or maintenance teams to ascertain whether their products, processes, or workspaces have been adversely affected by static electricity. This determination can be made by testing with a static meter, such as an electrostatic field meter or an electrostatic voltmeter. These instruments detect and quantify the presence of static charges on surfaces, materials, equipment, or personnel.

Upon confirming the necessity for static elimination, suppliers will address the issue by deploying one or more types of static eliminators or ESD (Electrostatic Discharge) products available to them. The selection process considers factors such as the nature of the static problem, material type, process speed, environmental conditions, and safety requirements. For example, facilities with flammable dust or vapors may require intrinsically safe static control devices, while electronics manufacturers prioritize ESD-safe tools and anti-static workstations.

Key steps for implementing static control solutions include:

- Identifying static-prone areas using static meters and process audits.

- Consulting with static control experts to select appropriate products (ionizers, grounding straps, anti-static mats, etc.).

- Properly installing and grounding static eliminators according to manufacturer guidelines and relevant safety standards.

- Training staff on the correct use and maintenance of static control equipment.

- Regularly monitoring static levels and maintaining equipment to ensure ongoing protection.

Want step-by-step guidance on static eliminator installation or troubleshooting? Contact a static control specialist or read our installation best practices guide.

Safety and Compliance Standards

The safety and compliance standards for static eliminators vary based on your application, industry, and location. In the United States, the National Fire Protection Association (NFPA) provides guidelines to reduce the risk of fires and explosions, particularly benefiting operators in printing, coating, and chemical processing industries. Additional U.S. organizations issuing standards include the military (Mil-Specs), the Electrostatic Discharge Association (ESDA), ANSI, the Nuclear Regulatory Commission (NRC), and the Food and Drug Administration (FDA) for medical and food equipment. Globally, the International Electrotechnical Commission (IEC) has been setting electrostatic discharge (ESD) standards since the 1980s, such as IEC 61340 for ESD control environments.

When selecting static eliminators and ESD protection products, ensure your supplier’s solutions meet all relevant standards for your industry and jurisdiction. Compliance not only ensures safe operation but may also be essential for quality certifications, insurance coverage, and legal requirements in sectors like electronics, healthcare, aerospace, and hazardous materials handling.

Common static control standards include:

- IEC 61340 (Electrostatics – ESD control)

- ANSI/ESD S20.20 (ESD Control Program Standard)

- NFPA 77 (Recommended Practice on Static Electricity)

- OSHA guidelines for static electricity control

- ISO 14644-5 (Cleanroom ESD protection)

- FDA regulations for medical device manufacturing

Are you unsure about which static control standards apply to your facility? Consult with an ESD compliance expert to ensure you meet all regulatory and industry requirements.

Benefits of Using Static Eliminators

Investing in high-quality static eliminators and ESD control solutions delivers numerous operational, safety, and cost-saving benefits across a broad range of industries:

- Improved Product Quality: Minimize defects, misprints, dust contamination, and ESD-related failures in electronics, printing, and packaging lines.

- Enhanced Workplace Safety: Reduce the risk of electrical shocks, equipment damage, and fires or explosions—especially in hazardous or flammable environments.

- Reduced Downtime: Prevent production stoppages caused by static clinging, jams, or ESD-induced system malfunctions.

- Cost Savings: Lower maintenance expenses, reduce scrap rates, and minimize warranty claims or returns due to static-related issues.

- Compliance and Certification: Meet regulatory, quality, and insurance requirements for static control, ESD-safe manufacturing, and cleanroom operation.

- Versatility and Flexibility: Choose from a range of static eliminator devices (bars, blowers, mats, sprays, brushes, gloves, etc.) to address unique process challenges and workspace configurations.

Considering the advantages of ESD protection and static control? Discover the right solution for your business or request a quote from leading static eliminator manufacturers.

Decision Factors: How to Choose the Right Static Eliminator

Choosing the most effective static eliminator for your facility or process involves evaluating several key decision factors:

- Type of Application: Identify whether your process involves continuous web materials, discrete parts, cleanrooms, hazardous zones, or general workspaces.

- Material Sensitivity: Consider the ESD sensitivity of your products (e.g., microelectronics, optical components, medical devices).

- Environmental Conditions: Assess humidity, temperature, dust levels, and presence of flammable or explosive materials.

- Process Speed and Scale: Factor in the speed of your production line and the size of the area requiring static control.

- Compliance Requirements: Ensure solutions meet all relevant standards (NFPA, IEC, ANSI/ESD, FDA, etc.).

- Installation Constraints: Evaluate available space, power sources, and integration with existing equipment.

- Maintenance and Support: Choose devices with accessible maintenance, diagnostics, and local technical support.

- Budget and ROI: Balance up-front investment with expected savings from improved quality, safety, and reduced downtime.

Not sure which static eliminator matches your requirements? Compare top static eliminator suppliers or use our product selection guide for step-by-step assistance.

Finding the Right Manufacturer

To find a suitable static eliminator, partnering with a reliable manufacturer is crucial. We have curated a list of top-rated static eliminator manufacturers to help you connect with a high-quality supplier, located in the middle of this page. Before starting your search, we suggest creating a personalized list of your specifications, requirements, questions, and concerns. Highlight crucial aspects such as budget, project timeframe, delivery preferences, and post-delivery support needs. Once your list is ready, explore the static eliminator suppliers and identify three or four that align most closely with your criteria. Contact each one to discuss your application in detail. Compare the conversations, considering prices and customer service quality. Finally, decide which manufacturer best fits your needs and reach out to finalize the deal.

Need help getting started? Browse our directory of static eliminator manufacturers or request a consultation to match your application with the best supplier.

Frequently Asked Questions about Static Eliminators

- What is the difference between an ionizer and a grounding device?

Ionizers generate positive and negative ions to neutralize static charges in the air or on surfaces, ideal for non-conductive materials and cleanrooms. Grounding devices provide a direct discharge path to earth for conductive objects, machinery, or personnel, widely used in electronics assembly and material handling. - How do I know if I need a static eliminator?

If you experience issues such as dust attraction, static shocks, material jams, print defects, or ESD-related equipment failures, it’s likely static is present and a static eliminator is needed. Testing with a static meter or consulting a static control expert can confirm the severity and best solutions. - Can static eliminators be used in hazardous or explosive environments?

Yes, but it’s essential to select devices certified as intrinsically safe or explosion-proof, and to comply with all relevant NFPA and OSHA standards for static control in hazardous locations. - What maintenance do static eliminators require?

Regular cleaning of emitters, checking for proper grounding, periodic calibration of static meters, and prompt replacement of worn parts are recommended to ensure reliable static control. - Are there portable or handheld static eliminators?

Yes, handheld ionizing blowers, brushes, and portable grounding testers are available for spot treatment or mobile use in field service, inspection, and repair scenarios.

Have more questions? Contact an anti-static solutions provider or read our in-depth static control FAQ.

Conclusion: Advancing Productivity and Safety with Static Control

Effective static elimination is a cornerstone of modern manufacturing, quality assurance, and workplace safety. By understanding the science behind static electricity, the range of static eliminator technologies, and the factors that influence product selection, businesses across diverse industries can mitigate risks, optimize processes, and protect valuable assets. Whether you need static control for electronics, printing, plastics, or hazardous environments, choosing the right static eliminator ensures compliance, quality, and long-term operational success.

Ready to take control of static electricity in your facility? Explore leading static eliminator manufacturers, request a custom quote, or consult with an ESD protection expert to find the ideal solution for your business needs.

Electric Coils

Electric Coils Electric Switches

Electric Switches Electric Transformers

Electric Transformers Electronic Connectors

Electronic Connectors Electronic Enclosures

Electronic Enclosures EMI Shielding

EMI Shielding Membrane Switches

Membrane Switches Power Cords

Power Cords Static Eliminators

Static Eliminators Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services