It is the first step in static elimination, which protects workers from harmful or even deadly electric shock, as well as prevents catastrophic failure, permanent damage and interference in sensitive electronic devices. Read More…

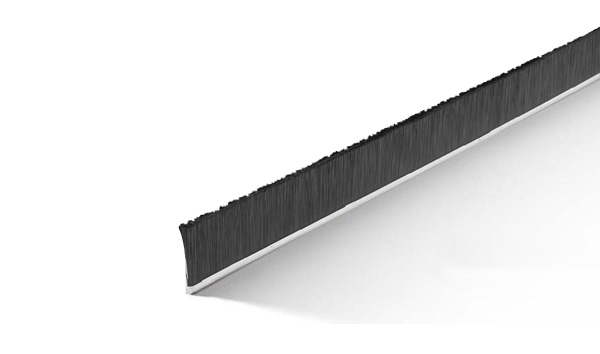

Gordon Brush’s® ESD & cleanroom products meet the specific needs of the electronics industry plus industries where static electricity buildup is detrimental to manufacturing.

TAKK Industries manufactures static eliminators for industrial processes and business machines. We also offer a full line of static eliminator blowers, spray, static detection meters and anti-static brushes. Some applications they can be used for are painting, plastic, textiles and more. If you have questions or need to meet certain specifications, don’t hesitate to contact TAKK Industries.

At Amstat Industries, we specialize in providing innovative solutions for static elimination, helping industries maintain optimal efficiency and safety in their operations. Our expertise lies in designing and manufacturing advanced static eliminators that effectively mitigate the challenges posed by electrostatic charges in a variety of industrial environments.

More Static Meter Manufacturers

Static meters measure voltage, field, charge and polarity without transferring any charge onto the actual instrument, as they are able to measure static electricity within inches of the surface area. After static electricity has been found, the next step in static elimination is to use an eliminator product, including anti static mats, gloves and ground straps to dissipate, conduct or balance the electrical charge. Besides troubleshooting a suspected ESD issue, static meters also test the performance of ionizers.

They are accurate, sensitive, responsive and able to work for long periods of time. They are simple and easy to operate, and often involve pressing a large red button with one finger. Static meters are used in manufacturing facilities that assemble and produce computer equipment, all electronics, medical equipment, cell phones and semiconductors.

Clean rooms, computer repair technicians and anyone doing work on internal electronic hardware should use a static meter to determine whether or not a static eliminating device is necessary. Static meters are small and require only a one-hand operation to press a red button while holding it close to the area in question.

Most static meters' readings are determined by their +/- accuracy between one and five percent, while others determine it according to the measured voltage. To improve the results, LED ranging lights are used to give a more detailed readout. The results are accurate if the instrument has been properly zeroed, the distance between the meter and the target is close enough and the target surface area is at least five square inches. 9v batteries are strong enough to power most portable static meters, and others come with an electrical cord and require plugging in to operate.

Because static meters tend to be costly, sensitive equipment, most manufacturers sell them with plastic or leather carrying cases so they are more protected in transit and storage. Static meters are more commonly seen in computer and electronics manufacturing facilities that work in areas with the risk of static build up.

Computer repair and at-home maintenance rarely use static meters and choose to acquire static eliminating devices instead because they are much less expensive, and get the job done immediately rather then making it a two step process.

Electric Coils

Electric Coils Electric Switches

Electric Switches Electric Transformers

Electric Transformers Electronic Connectors

Electronic Connectors Electronic Enclosures

Electronic Enclosures EMI Shielding

EMI Shielding Membrane Switches

Membrane Switches Power Cords

Power Cords Static Eliminators

Static Eliminators Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services