Anti-static sprays are effective in hard-to-reach places or blocked surfaces, for products that move at rapid speeds, and on surfaces with an extremely high static charge. Read More…

Gordon Brush’s® ESD & cleanroom products meet the specific needs of the electronics industry plus industries where static electricity buildup is detrimental to manufacturing.

TAKK Industries manufactures static eliminators for industrial processes and business machines. We also offer a full line of static eliminator blowers, spray, static detection meters and anti-static brushes. Some applications they can be used for are painting, plastic, textiles and more. If you have questions or need to meet certain specifications, don’t hesitate to contact TAKK Industries.

At Amstat Industries, we specialize in providing innovative solutions for static elimination, helping industries maintain optimal efficiency and safety in their operations. Our expertise lies in designing and manufacturing advanced static eliminators that effectively mitigate the challenges posed by electrostatic charges in a variety of industrial environments.

More Anti-Static Spray Manufacturers

Anti Static Spray: Comprehensive Guide to Static Control Solutions

In both industrial and household environments, static electricity can cause a range of problems—attracting dust, damaging sensitive electronic components, and compromising the performance of various devices. Anti static sprays are a practical and effective solution for minimizing static charge, protecting valuable equipment, and creating safer, cleaner workspaces. This guide explores everything you need to know about anti static sprays, including their uses, benefits, application methods, and how to choose the best anti static spray for your needs.

What Is Anti Static Spray?

Anti static spray is a specially formulated liquid designed to prevent the buildup of static electricity on surfaces. By applying the spray and wiping it off, you create a protective layer that neutralizes electrical charges and reduces static cling, effectively repelling dust and minimizing the risk of electrostatic discharge (ESD). Unlike some other ESD products, anti static spray is simple to use and suitable for a wide variety of surfaces, making it an essential part of any static control program.

How Does Anti Static Spray Work?

Static electricity arises from an imbalance of positive and negative charges, often created when two materials rub together—a process called tribocharging. If not managed, this imbalance can result in electrostatic discharge, which can damage delicate electronics or attract dust particles. Anti static sprays work by increasing the conductivity of the treated surface, dissipating static charges and making it more difficult for static to accumulate. The application is straightforward: spray onto the surface, wipe clean, and benefit from immediate static protection without any residue or corrosion. For those searching for "how does anti static spray work" or "anti static spray mechanism," this process is key to understanding its effectiveness in a wide range of environments.

Key Features of Anti Static Spray

- Reduces static buildup on multiple surfaces including plastics, metals, textiles, and glass

- Repels dust and dirt effectively, supporting cleanroom and contamination control

- Non-corrosive and safe for sensitive electronics, laboratory instruments, and optical devices

- Leaves no residue—just a fresh, clean scent for improved indoor air quality

- Enhances surface contact resistance, supporting robust ESD prevention strategies

- Quick and easy application, making it convenient for both industrial and household users

- Compatible with other ESD-safe products for layered protection

Applications: Where to Use Anti Static Spray

Anti static spray is a versatile tool with uses that span from industrial static control to everyday household applications. Here are some common uses and industries that benefit from anti static products. If you're wondering "where can I use anti static spray?" or "is anti static spray suitable for electronics, fabrics, or plastics?"—this section will answer your questions.

Electronics and IT Equipment

In electronics manufacturing facilities, laboratories, data centers, and offices, anti static spray is essential for:

- Preventing electrostatic discharge on circuit boards, motherboards, and sensitive components

- Protecting computers, laptops, tablets, and smartphones from static-related damage

- Reducing dust accumulation on monitors, keyboards, and server racks

- Maintaining the longevity of printers, photocopiers, and fax machines

- Maintaining ESD-safe workstations in assembly and repair operations

- Optimizing the reliability and lifespan of industrial automation systems

Photography and Optics

Static electricity can attract dust to high-precision optical devices, leading to compromised image quality and reduced equipment performance. Anti static spray is used to:

- Clean and protect camera lenses, filters, and sensors

- Reduce static on photographic films and negatives

- Maintain clarity in microscopes and telescopes

- Protect optical instruments in laboratories and research environments

- Preserve the performance of fiber optic cables and connectors

Printing and Graphics

Printing presses and graphic design environments often encounter static-related issues. Anti static spray helps by:

- Preventing paper jams and misfeeds in printers and copiers

- Reducing dust and static attraction on paper and film stocks

- Improving print quality and reducing material waste

- Maintaining smooth transport of materials on rollers and conveyors

- Supporting packaging, labeling, and production quality assurance

Textiles and Apparel

Static cling is a common nuisance in clothing and textiles. Anti static sprays are effective for:

- Eliminating static from clothing, curtains, and upholstery

- Reducing dust buildup on carpets and rugs

- Making work environments in textile factories safer and more comfortable

- Preserving the integrity of sensitive fabrics and fibers including synthetics and blends

- Improving the quality and finish of garments in textile manufacturing

Household and Office Uses

Beyond industrial applications, anti static sprays are invaluable in homes and offices:

- Reducing static on telephones, light fixtures, and electronic devices

- Keeping walls, ceilings, and furniture dust-free

- Maintaining the appearance of glass, metal, and plastic surfaces

- Protecting home electronics from static shock

- Improving air quality by minimizing airborne dust attraction

- Enhancing comfort in dry climates or during winter months when static is more prevalent

Why Use Anti Static Spray? Key Benefits for Buyers

Users seeking reliable static control solutions often ask, “What are the main advantages of using anti static spray?” Here are some compelling benefits for both industrial and personal use. If you’re comparing static control methods, consider these points as part of your decision-making process:

- Electrostatic Discharge Protection: Prevents costly ESD damage to electronics, which can lead to data loss, equipment failure, or warranty voids in high-value assets.

- Dust Repellence: Keeps surfaces cleaner for longer by minimizing dust and particulate adhesion, reducing cleaning time and maintenance costs.

- Improved Safety: Reduces the risk of static shock to personnel, especially in ESD-safe workspaces and cleanrooms, supporting workplace health and safety compliance.

- Enhanced Productivity: Minimizes interruptions and maintenance demands caused by static-related issues, yielding higher efficiency and reduced downtime.

- Surface Versatility: Effective on metal, plastic, glass, fabrics, rubber, acrylics, and more—making it an all-purpose choice for static control.

- Non-Damaging Formula: Many anti static sprays are free of harsh chemicals, ensuring they are safe for delicate surfaces and environmentally friendly, with low VOC formulations available.

- Ease of Use: Quick to apply with no special training required, suitable for both professionals and home users.

- Cost-Effective: Reduces the need for replacement parts and frequent cleaning, providing a high return on investment for facilities managers and consumers alike.

Looking for ways to increase the lifespan of your electronics or eliminate static on your work surfaces? Anti static sprays are a cost-effective and efficient solution trusted by professionals worldwide. For more advanced ESD protection, consider integrating additional static control products such as anti-static gloves, static shielding bags, and ionizers into your workflow. Wondering "what is the best anti static spray for electronics?" or "how to build a complete ESD program"? Read on for more expert tips.

How to Apply Anti Static Spray: Step-by-Step Guide

Not sure how to use anti static spray for best results? Follow these steps for safe and effective static elimination. These instructions address common search queries such as "how to use anti static spray," "application instructions," and "anti static spray directions."

- Check the Surface: Ensure the area is clean and free of dust or debris before application. Pre-cleaning optimizes spray performance.

- Shake the Spray: If required, shake the bottle well to mix the solution evenly. Some formulations settle over time.

- Apply Evenly: Spray a light, even coat onto the surface from a distance recommended by the manufacturer (usually 6–12 inches).

- Wipe Down: Use a clean, lint-free cloth to wipe the surface, spreading the solution and removing excess liquid. This ensures full coverage without streaking.

- Allow to Dry: Let the surface air dry for a few moments. Most anti static sprays dry quickly and leave no residue.

- Repeat as Needed: For high-traffic or high-use surfaces, reapply regularly to maintain static protection. Frequency depends on environmental conditions and usage.

Always follow the manufacturer’s instructions for optimal results. For sensitive electronics, confirm the spray is specifically labeled as safe for electronic equipment. Wondering "can you use anti static spray on computers or LCD screens?"—always check product compatibility before use.

Choosing the Right Anti Static Spray for Your Needs

When searching for the best anti static spray, you may wonder: “Which anti static spray is safe for electronics?” or “What’s the difference between industrial and consumer-grade sprays?” Consider these factors before making a purchase. If you’re evaluating products, think about these decision points to find the most suitable solution:

- Surface Compatibility: Ensure the product is suitable for the materials you need to treat, such as plastics, metals, fabrics, or glass. Some anti static sprays are formulated specifically for electronics, while others are general purpose.

- Spray Formulation: Look for non-conductive, non-corrosive formulas—particularly for use on electronics and optical devices. Alcohol-free and solvent-free sprays are often preferred for sensitive equipment.

- Size and Packaging: Choose from small bottles for portable use to large industrial containers for bulk applications. Consider aerosol vs. trigger spray options for convenience.

- ESD Certification: For sensitive environments, select sprays certified for ESD-safe performance, such as those complying with ANSI/ESD S20.20 or IEC 61340 standards.

- Environmental Impact: Opt for eco-friendly, aerosol-free sprays when possible to minimize environmental harm. Look for biodegradable and low-toxicity options.

- Brand Reputation: Purchase from trusted manufacturers with positive reviews and proven track records in static control solutions. Research product reviews and ask for technical data sheets if needed.

- Performance Longevity: Check how long the anti static effect lasts and how often reapplication is required.

- Price and Value: Balance cost with performance, coverage area, and frequency of use for the best value.

Explore our full range of ESD products and accessories to find the perfect combination for your static control needs. Searching for "anti static spray near me" or "bulk anti static spray suppliers"? We offer fast shipping and expert support to help you make the right choice.

Common Questions About Anti Static Spray

Is anti static spray safe for electronics?

Most modern anti static sprays are formulated to be non-conductive and non-corrosive, making them safe for use on electronic components, circuit boards, and devices. Always verify that the product label specifies compatibility with electronics before application. For those managing mission-critical IT or laboratory equipment, choose products specifically tested for electronic safety.

Can anti static spray be used on clothing?

Yes, many anti static sprays are designed for use on textiles, including clothing, upholstery, and carpets. They help to eliminate static cling and reduce dust buildup, making fabrics more comfortable and attractive. Be sure to test on a small, inconspicuous area first, especially on delicate fabrics or colored materials.

How long does anti static spray last?

The effectiveness of anti static spray can vary depending on the environment and level of use. In general, protection lasts from several days to a few weeks. Reapplication is recommended for sustained static control, especially in high-traffic or high-dust areas such as data centers, cleanrooms, or busy offices.

Are there alternatives to anti static spray?

Yes, other ESD control products—such as ESD mats, wrist straps, static brushes, and ionizers—can complement or substitute for anti static sprays in certain applications. Combining multiple static control solutions often yields the best results. For comprehensive ESD protection, establish an electrostatic protected area (EPA) using a layered approach.

Where can I buy high-quality anti static spray?

You can purchase anti static spray online from specialized static control suppliers, electronics retailers, or industrial safety providers. For a curated selection of the best anti static sprays and related ESD solutions, browse our online store or contact us for expert recommendations. Looking for "anti static spray for electronics," "anti static spray for clothes," or "industrial anti static spray"? We can help you choose the right product for every application.

Does anti static spray damage surfaces or electronics?

High-quality anti static sprays are designed to be safe for a variety of surfaces and electronics. However, always check the manufacturer's instructions and test on a small area if you are unsure. Some surfaces, such as untreated wood or specialty coatings, may require a tailored approach.

Can anti static spray be used in cleanrooms?

Yes, many anti static sprays are formulated for cleanroom compatibility, offering low outgassing and minimal particulate generation. Always review technical data to ensure the product meets cleanroom or laboratory standards.

Integrating Anti Static Spray with Complete ESD Protection

While anti static spray is an essential part of static control, optimal protection for sensitive electronics, manufacturing environments, and laboratories often requires a holistic approach. Consider combining anti static spray with these ESD control products and practices:

- Anti-static gloves for safe handling of delicate components

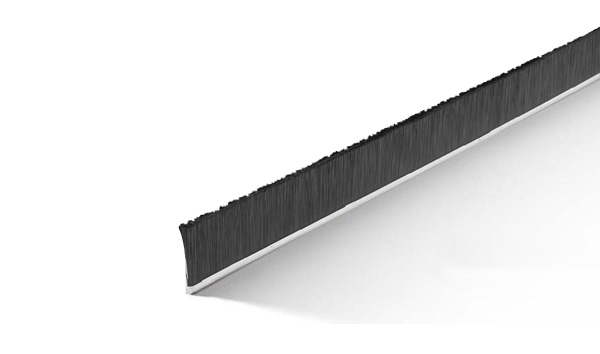

- Static brushes for cleaning intricate parts

- Ionizers for neutralizing airborne static charges

- Regular staff training on ESD-safe protocols and best practices

- Routine ESD audits and monitoring to identify and mitigate risks

By integrating these solutions, you create an electrostatic protective area (EPA) that maximizes the safety and reliability of your sensitive electronic equipment and processes. This layered approach answers questions like "how to prevent ESD in electronics manufacturing" and "what are the best practices for static control in the workplace?"

Understanding Static Electricity and Its Dangers

Static electricity is the accumulation of an electrical charge on the surface of materials, often as a result of friction between objects. When this charge is suddenly released—known as electrostatic discharge (ESD)—it can cause:

- Data loss or corruption in computers and data storage devices

- Physical damage to microchips, transistors, and other components

- Malfunction or failure of medical devices and laboratory equipment

- Production delays in manufacturing environments

- Increased cleaning and maintenance costs due to dust attraction

- Potential fire or explosion risks in flammable or solvent-rich environments

- Reduction in product quality in sensitive industries like pharmaceuticals, semiconductors, and automotive manufacturing

Even low voltage ESD events can be problematic, as many electronic components are extremely sensitive to static discharge. While metals can be grounded to discharge static, insulators (like plastics) do not conduct electricity and require additional static control measures, such as anti static sprays and ESD-safe equipment. If you’re curious about "what causes static electricity" or "how ESD affects electronics," this knowledge is vital for protecting your investments.

Best Practices for Static Control in the Workplace

To safeguard your critical assets, follow these best practices for comprehensive static control:

- Establish electrostatic protective areas (EPAs) in electronics manufacturing, repair, and assembly environments

- Require the use of anti-static gloves, ESD mats, and static shielding bags

- Regularly apply anti static spray to work surfaces, tools, and equipment

- Train employees on ESD awareness and safe handling procedures

- Conduct routine checks for static buildup and potential ESD hazards

- Implement humidity control to reduce static generation in dry environments

- Use ionization equipment in areas with high concentrations of non-conductive materials

- Maintain proper maintenance and cleaning schedules for all ESD control devices

Proactively managing static electricity not only protects sensitive electronics but also reduces downtime, improves productivity, and ensures compliance with industry safety standards. If you’re searching for "how to prevent ESD damage" or "static control policies for electronics manufacturing," these practices are essential for success.

Summary: Why Anti Static Spray Is Essential for Static Control

From electronics and optics to textiles and printing, anti static spray is a simple yet powerful tool for minimizing static-related risks in virtually any environment. By investing in high-quality anti static sprays and complementary ESD control products, you protect your equipment, enhance workplace safety, and enjoy cleaner, more reliable workspaces.

Ready to find the best anti static spray for your needs? Explore our full range of anti static sprays and ESD products or contact our experts for personalized recommendations. Stay protected, stay productive—make static control a priority today.

Additional Resources and Next Steps

If you’d like to learn more about static control, explore these related topics:

- What are the best static brushes for cleaning electronic components?

- How do ionizers work to neutralize airborne static?

- What regulations govern ESD protection in the electronics industry?

- How to train your team on ESD awareness and compliance?

For more information or to request a quote, reach out to our technical support team today. Whether you’re an engineer, facilities manager, or home user, we’re here to help you build a static-free environment with the industry’s most effective solutions.

Electric Coils

Electric Coils Electric Switches

Electric Switches Electric Transformers

Electric Transformers Electronic Connectors

Electronic Connectors Electronic Enclosures

Electronic Enclosures EMI Shielding

EMI Shielding Membrane Switches

Membrane Switches Power Cords

Power Cords Static Eliminators

Static Eliminators Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services